Supply Chain Transformation: Inbound opsConsumer Products - Spain

Very large food company.

The firm was growing at 25% per year, and it had been focused on building best in class production capabilities.

The company identified an opportunity to improve its profitability materializing supply chain efficiencies by reviewing its logistics model.

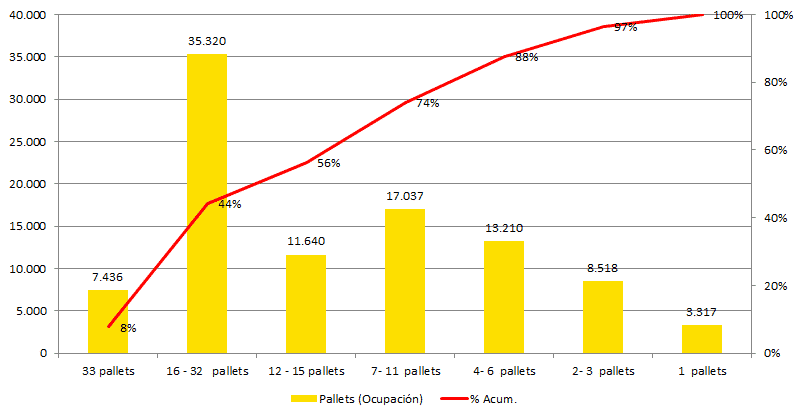

The challenge was to optimize the inbound logistics for 16 factories, which meant to improve the logistics of 270 suppliers that delivered more than 36.000 shipments per year, and more than 228.000 pallets per year.

Thus, the initial goal was to move the management of the inbound transportation from suppliers to the firm in order to get a transportation cost saving higher than 10%.

The optimization had to consider FTL, LTL and Consolidation Centers.

The solution was to use a Logistics Service Provider in order to avoid increasing the business complexity at the same time that the firm get important cost reductions. Moreover, using a third-party logistics provider could accelerate the cost saving project and reduce the risk of a supply chain disruption.

The main improvement initiatives executed were:

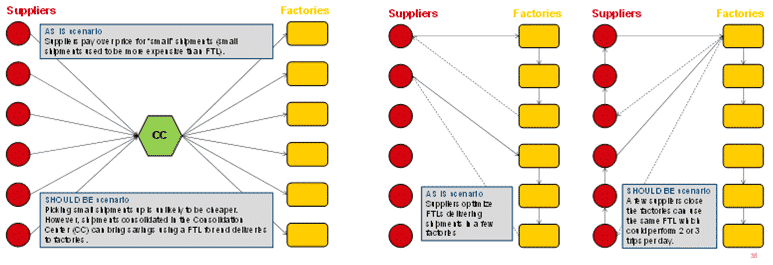

- For “small” shipments, we created milk runs using a supplier Consolidated Center (CC).

- We moved from milk runs of factories to milk runs of close suppliers and factories.

- We optimized the number of trips per FTL.