Define the Optimal USA Distribution Center LocationConsumer Products

One of the world leaders in aluminum solutions.

Products: Value-added profiles, profile-based building systems and heat-exchanger solutions.

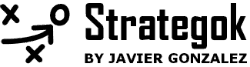

The customer needed to decide a new location for the new outsourced Distribution Center (DC) in USA. This important decision was going to influence importantly in the future distribution costs, and affecting customer service via lead-time.

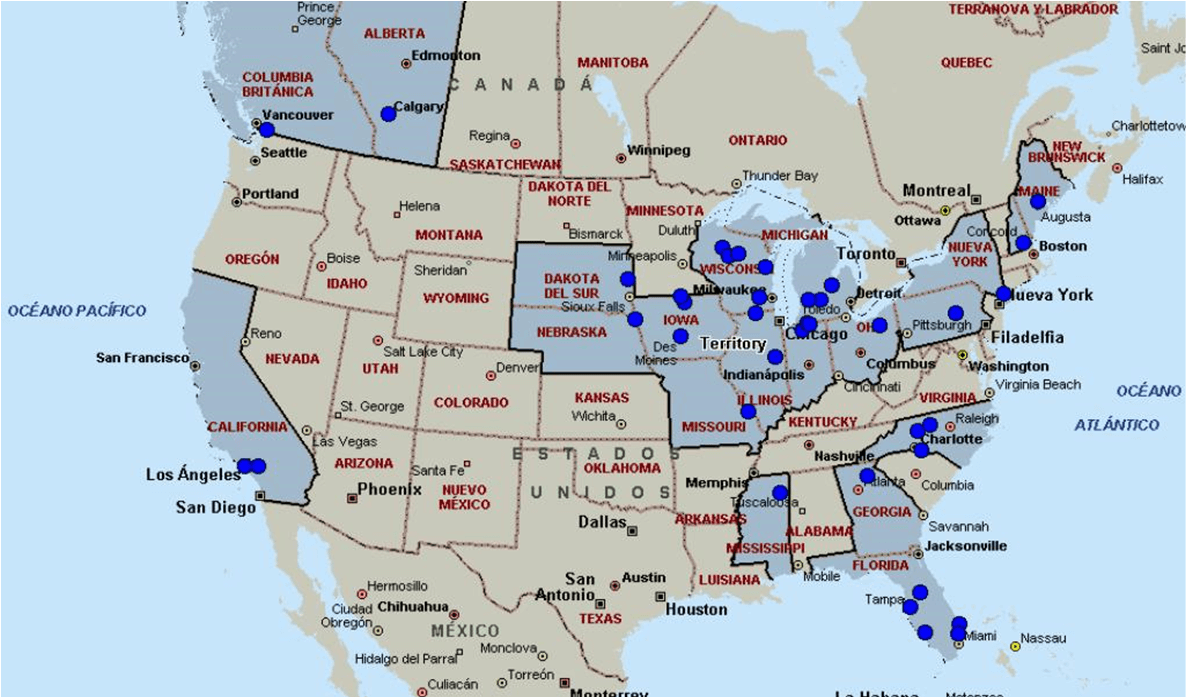

We had to collect data regarding customers’ location and volume to be able to perform the quantitative analysis (the center of gravity method). Additionally, other data were collected for the qualitative analysis (the factor rating method).

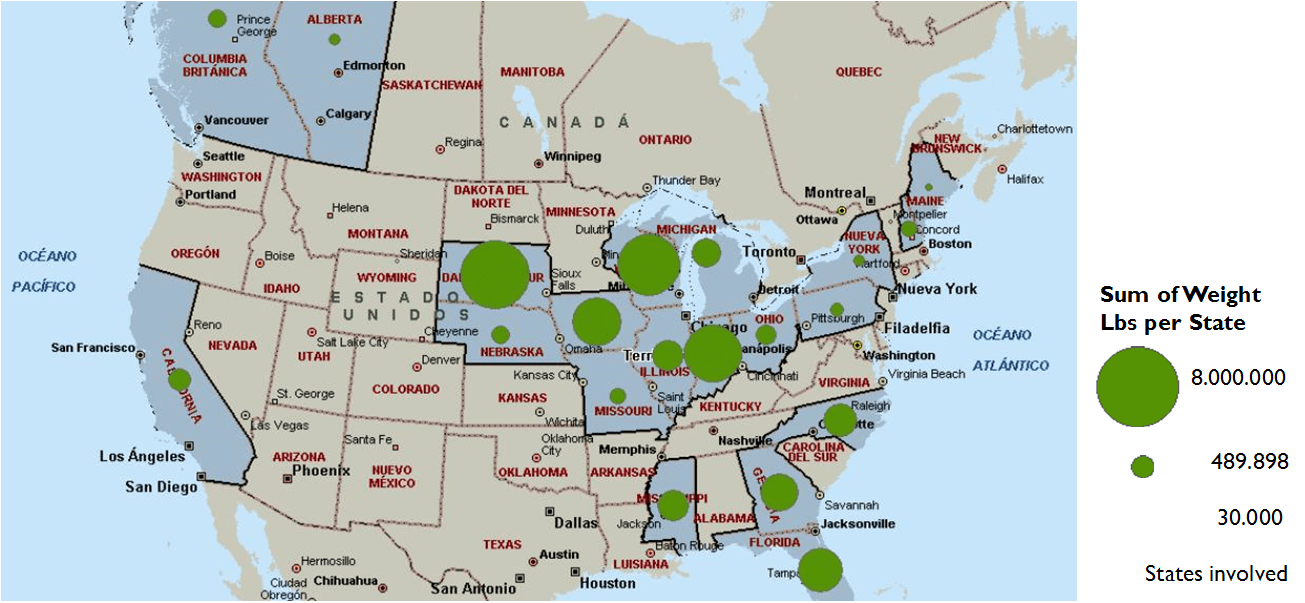

The center of gravity method is a mathematical technique used to find the location of a Distribution Centers (DCs) that will minimize distribution costs. The method considers the location of customers and markets, the volume and weight of goods shipped, and shipping costs.

The center of gravity suggested to locate the DC close to Roscoe (Chicago – Illinois). So, the next step was to confirm the quantitative analysis suggestion with the qualitative analysis. I mean labor costs (wages, productivity), labor availability (skills, attitudes), proximity to factories and suppliers, government fiscal policies (incentives, unemployment compensations), environmental regulations, utilities (electricity, gas, and water), site costs (land, expansion), transportation availability (interstate roads, rail, air, water), quality of life issues, quality of government (honesty, attitude toward new business), and so on.

-

Competitive distribution costs

-

Optimum customer response