Distressed Turnaround in BRAZIL: Supply Chain TransformationAutomotive - Brazil

One of the leading worldwide providers of diesel engines and complete drive systems for ships, land and rail-mounted vehicles, and industrial applications. Moreover, onsite energy systems, based on diesel engine, gas engine and gas turbine technology.

One of the company subsidiaries was facing important profitability problems during the last years. Therefore, the goals were the following:

- Reduce stock to improve the working capital of the company.

- Improve productivity.

- Improve service level.

- Increase profitability.

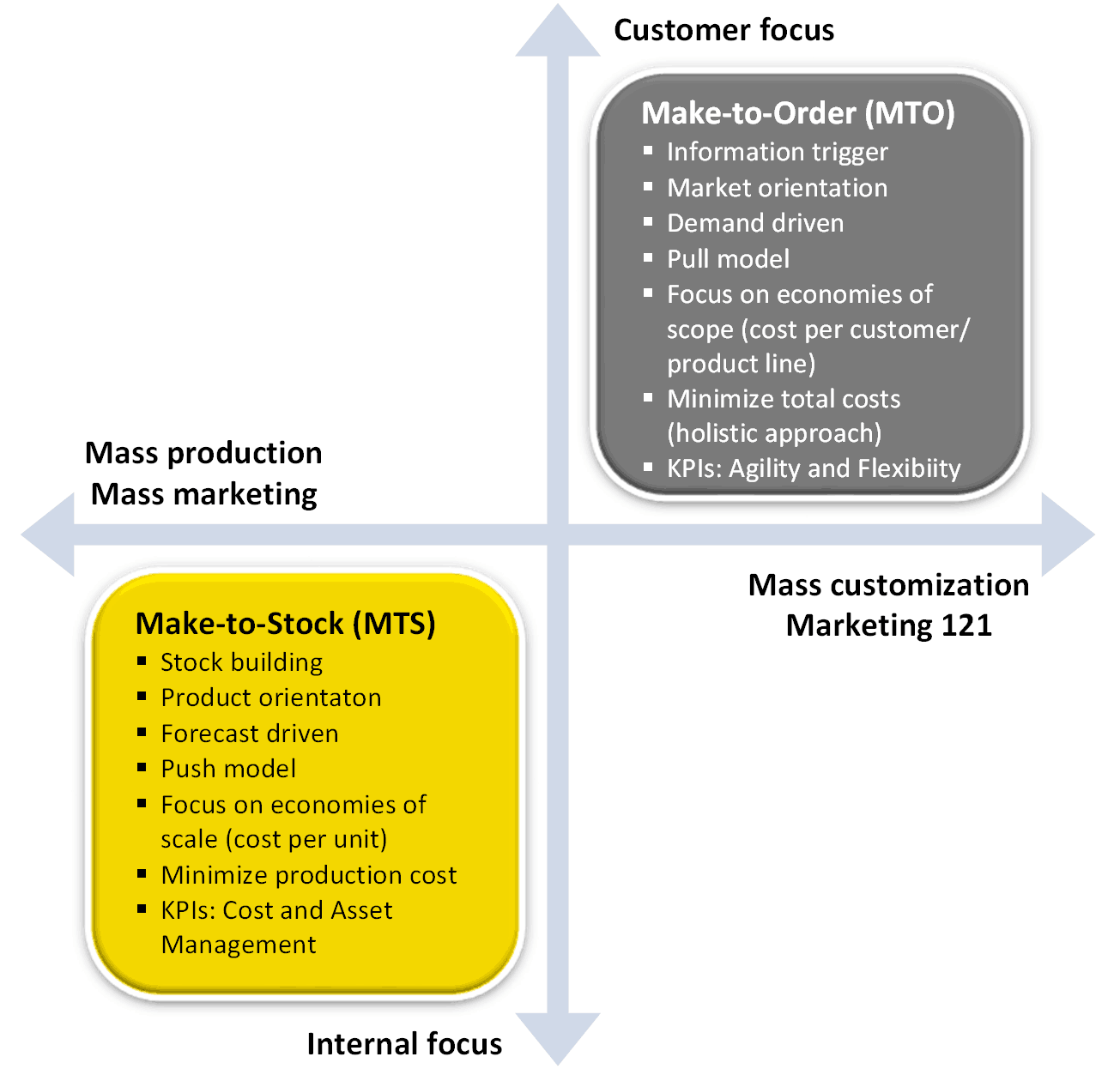

The firm was using forecast driven approach. The forecast was based on sales department experience, which was not working because customers used to change their product/engine strategy and there was no good coordination between both companies. The result was an overstock of finished engines; overstock of production parts due to unreliable forecast; unsatisfied customers because the sales forecast and make-to-stock strategy were not providing a better service. Indeed, the customer expectation regarding lead-time was much higher than the real lead-time.

The solution was implementing a lean production approach moving from make-to-stock scenario to make-to-order. The new solution brought improvements in the Balance and the Profit & Loss account of the company while customer satisfaction was improved too.

The main improvement initiatives were:

- Engines Finished Goods (FG) reduction.

- Engines FG in third party reduction.

- Spare Parts Raw Material (RM) reduction.

- Better sales forecast accuracy.

- Higher customer satisfaction.

We put in place a reliable make-to-order plan that allows us to deliver our promises to our customers. Moreover, our customers took advantage of the new reliable delivery date to get higher satisfaction from their end customers.

Additionally, a study of profitability by customer and engine was performed. So unprofitable low volume variants were phased out (complexity reduction), and unprofitable high-volume variants were pricing reviewed to improve profitability.

This new lean approach required to improve the communication and flexibility of our supplier Mercedes-Benz. So, weekly planning meetings were conducted, and in a few months, we could recover Mercedes-Benz trust in our planning process again.

The new production planning and make-to-order strategy allowed us to optimize resources and improve:

-

20% increase productivity

-

Improve working capital

-

Increase profitability