Lean Transformation: Factory logisticsMill Products - Spain

Very large international brewery group.

The company was growing a lot via acquisitions and natural growth. That growth for being sustainable required to reduce complexity, and increase efficiency.

Outsourcing offered not just an opportunity to increase efficiency, but also a partnership with a logistics service provider that could bring saving by better and specialized logistics management.

The factory had two big handicaps: important space constraints, and huge peak seasons of around 100%, which made complex to manage operations, and maintaining costs under control.

This outsourcing project was defined to not affect negatively to any current worker. Therefore, a social responsibility approach was put in place offering workers very good conditions for being retired or moving from logistics to production. So, there was not any resistance to this outsourcing initiative. Indeed, everybody cooperated to get a smooth transition process to the outsourcing firm.

The logistics service provider had much lower wages with higher productivity due to its specialization (reducing the waste of knowledge). Although, the outsourcing firm got a fee for its services, there was a huge saving for the manufacturing firm.

Other initiatives were implemented to reduce or avoid costs. Thus, the handling equipment cost was reduced using higher power negotiation of the third-party logistics firm. An initiative to reduce over time was created (the waste of over-processing). Moreover, there was an initiative reducing absenteeism and improving people punctuality to raise productivity.

One of the major impact initiatives was to redesign a new layout that increased productivity (reducing the waste of movement) and reduce the cost of product breakage (waste of making defective services).

Other important initiative to raise productivity was the upgrade most of the handling equipment to increase the handling capacity for movement (waste for movements).

A Total Productive Maintenance (TPM) initiative (planning equipment maintenance properly) reduced the equipment downtimes, and increase productivity again (waste of waiting).

Improving the slot booking process reduced unload lead times (waste of waiting) which was very important because the factory had important slots’ constraints.

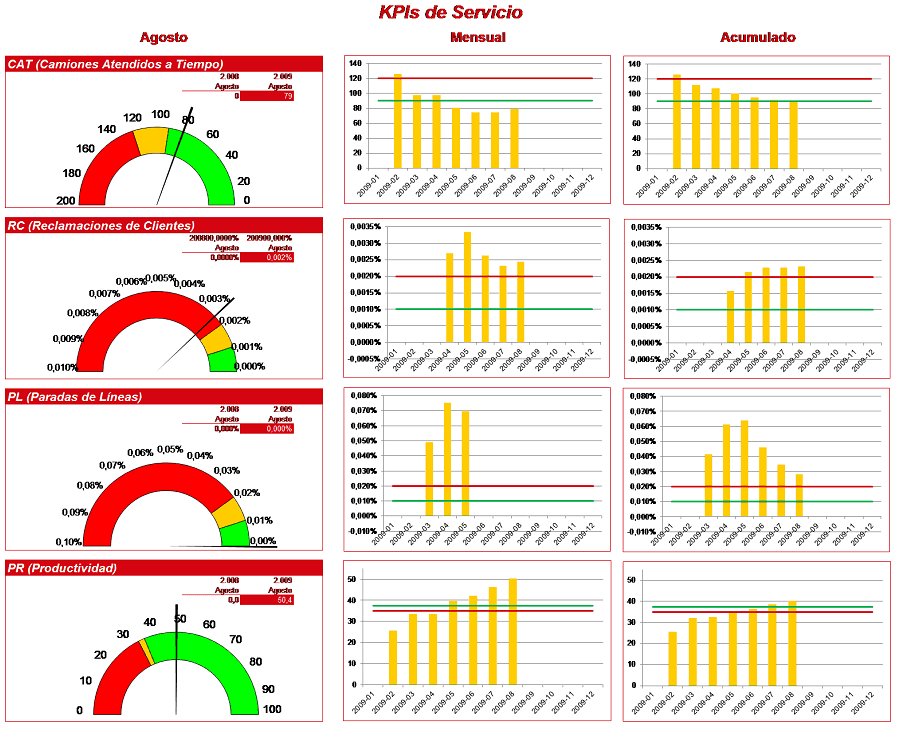

Finally, we started to measure improvements, creating a Logistics Scorecard.